Custom CNC

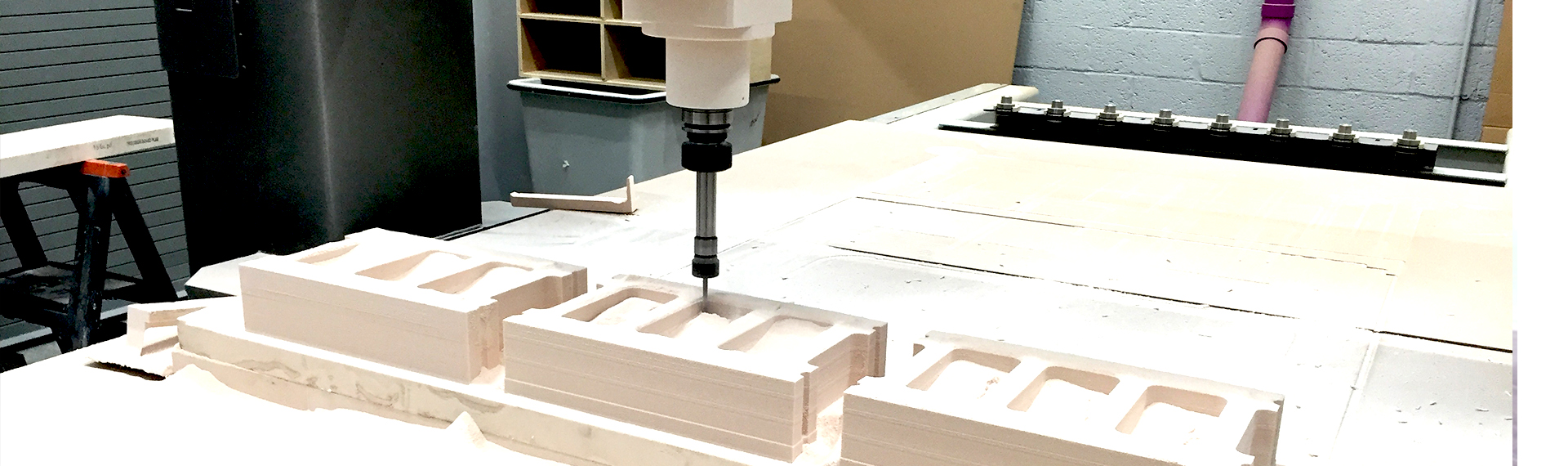

NVS offers high quality and precision CNC cutting, routing and milling. Our equipment allows for a 3 and 5 axis routing, and a seamless cutting are of 10th x 7’ x 3’ . As many NYC fabrication shops we can create amazing things with our CNCs, but what makes us different is the turnaround time. Custom CNC can be used for the following:

Custom CNC service, for two or three dimensional projects.

MATERIALS

Our CNCs cane work with many different material types and thicknesses.

Foam

Compressed foam is light, and routs at a high detail. from 1/4`` do 1`` thick.

Wood

Sustainable, and great CNC material. From plywood to hardwood.

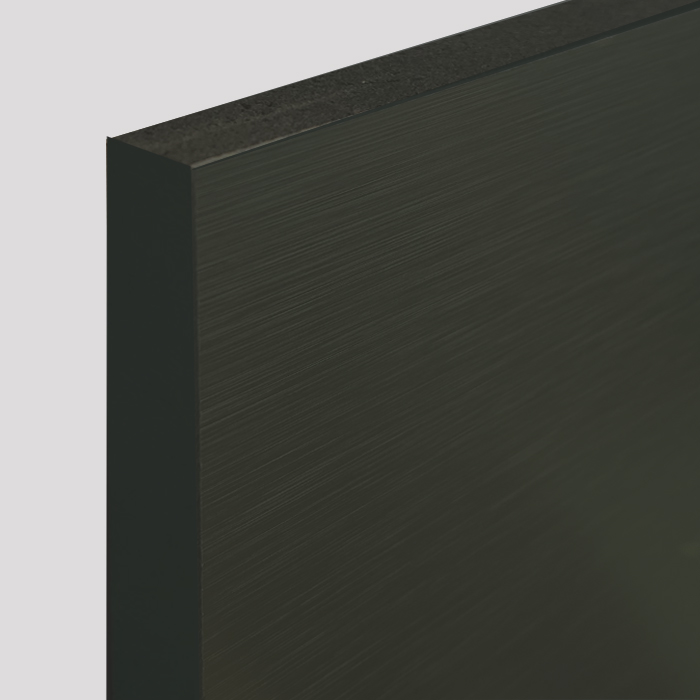

MDF

Less expensive than wood, rigid and one of most popular CNC materials.

Acrylic

We stock plexiglass sheets at different thicknesses from 1/8`` to 1``, and colors.

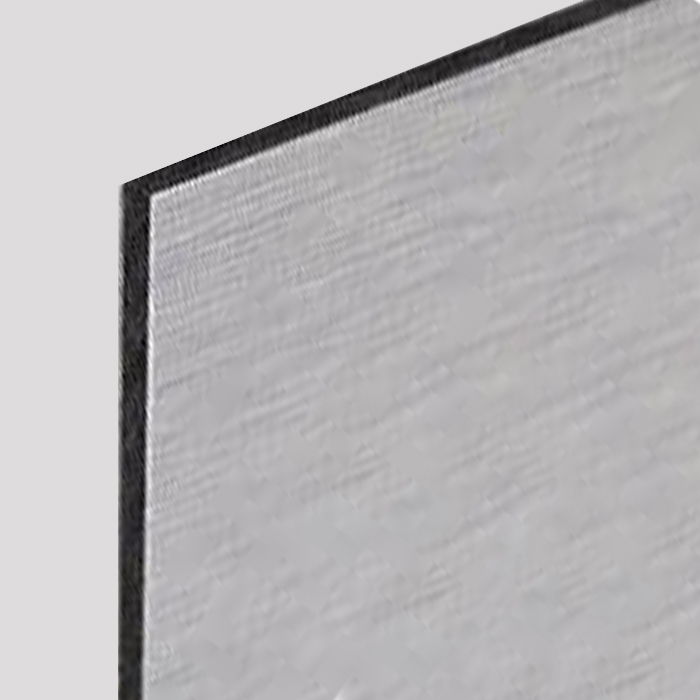

Aluminum

We can rout DiBond and aluminum. This metals come in different colors and finishes.

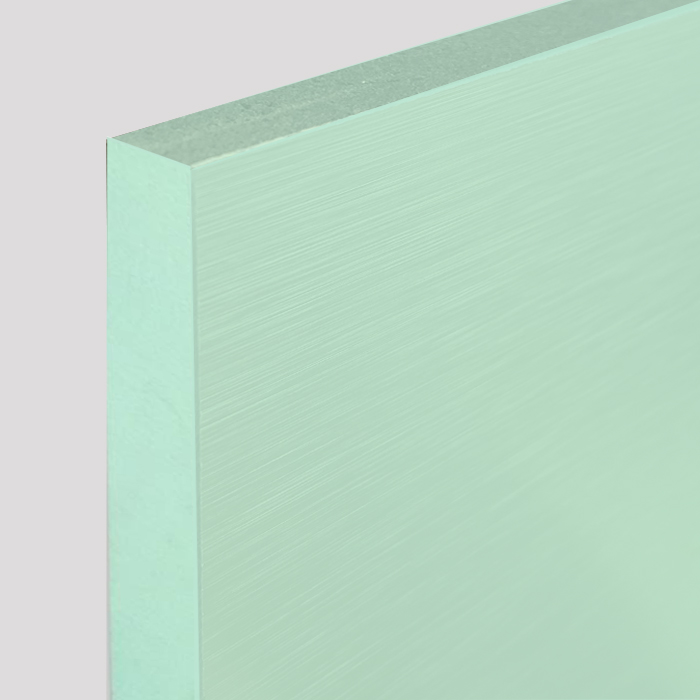

PVC

PVC comes in many colors and thicknesses from 1/8`` to 1``

Custom CNC

CNC is not as straightforward as you might think. There are many different materials, that are best selected when the application of the final work is onsidered. In addition, to every material there is a multitude of finishing options, and even fabrication processes. But, don;t worry – at NVS we got you covered.

Our 3 and 5 axis routing capability, cutting not only wood, but also metals with plasma routers, lets us build anything and everything.

Laser Cutting & Engraving

From making small engravings as custom made coins, to high precision plexi cuts – laser engraving is a great option for many custom cut objects, that are too small or too fragile for a CNC. Our C02 lasers can cut paper, engrave in chocolate, or bottles with rotary function.

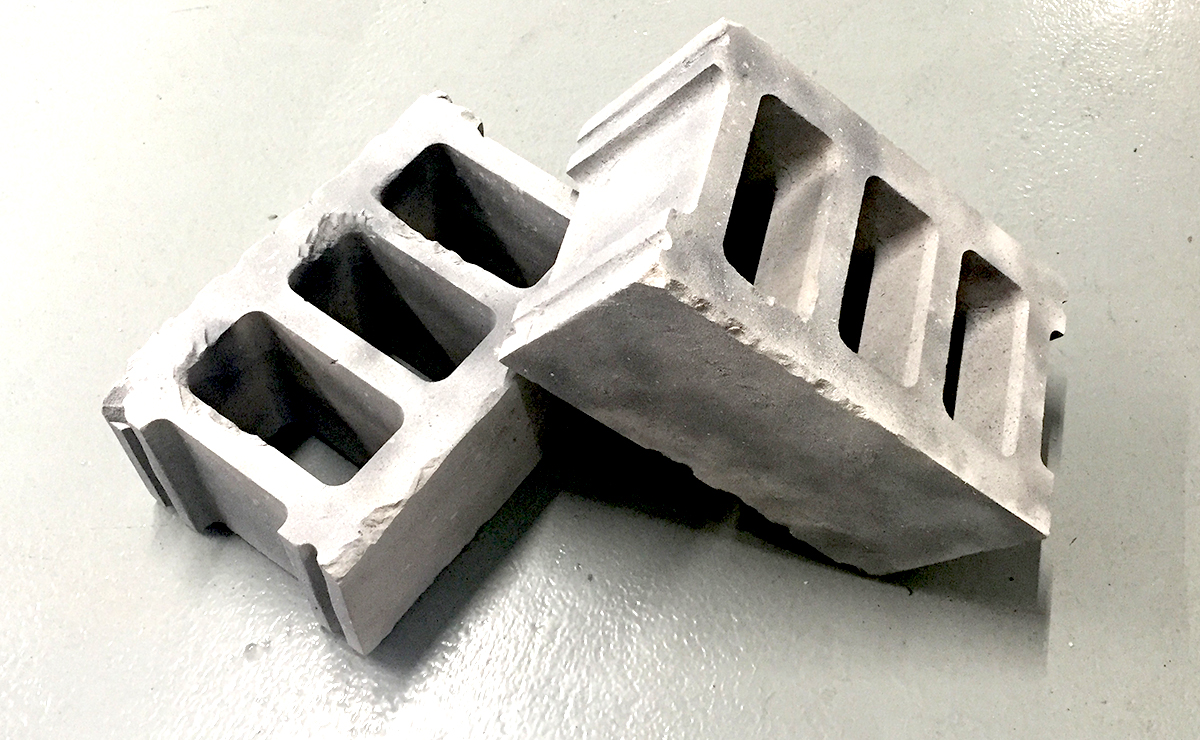

Dimensional Graphics

Dimensional graphics are growing more and more in popularity, and to create them we use our custom CNC and Milling capabilities. From custom cut foam letters, to standout logos and strange objects – crating things and objects is a merger of all of our print, cutting, design and fabrication capabilities. It’s easy to get lost in all of the possible solutions for building three dimensional visuals – but hey, we never get tired of it! Let us know what your next project consists of, and we’ll get to work.

How to get started

As with any service, NVS provides a fully customizable approach to CNC and Milling. From the size, application, mounting and materials – there are multiple options to choose from.

Concept Design

Let’s start the project by talking about the design. IF you have a concept, we can transform that into executable files – or if you need help with conceptualizing your idea – we can help as well.

Prototyping

Once we have our plan, we can start the process of prototyping and testing. Our fabrication capabilities allow us for approaching your project in several different ways. We first test to give you the best suitable solution.

Production

Once the sample is approved, we can proceed with production. Please ask us what is the production timing for your particular project. Since all we do is custom build-outs the timeline varies per project basis.

Installation & Mounting

If your projects needs installation and mounting, we can do that too. We have a fleet of vehicles and technicians who can deliver and assemble it on set.

DON’T BE SHY, SAY HELLO!

NVS Visuals

53-25 Metropolitan ave

Ridgewood, NY 11385

Ring Us

212-692-9727

Email Us

info@nvsvisuals.com